Aqua

Controller for automating hydroponic systems.

Controller for automating hydroponic systems.

Highly effective automation of nutrient solution preparation and delivery for advanced hydroponic systems.

Scheduled

nutrient delivery

Optimised cultivation recipes for 60+ varieties

App control for

convenient management

Air climate controller compatible

LEARN MORESet your desired EC and pH parameters and Aqua will control the preparation of the nutrient solution. Your desired irrigation schedule will then determine its delivery.

Easily grow your farm with the Visionary Farms app

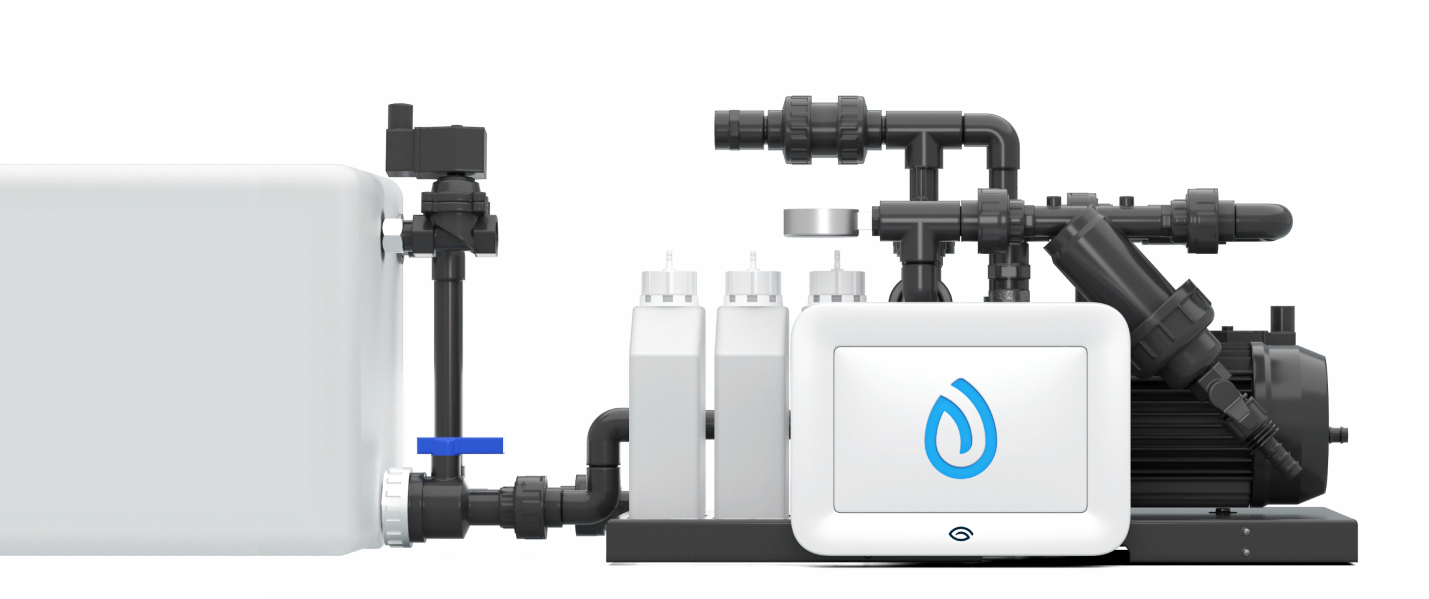

The Mixer is a series of pumps, valves and sensors within a farm controlled using the Aqua controller. Below is a demonstration of how different modes control the flow of nutrients.

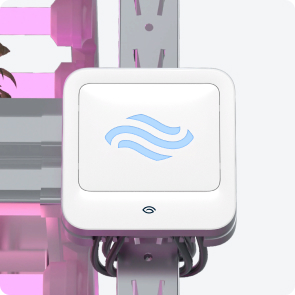

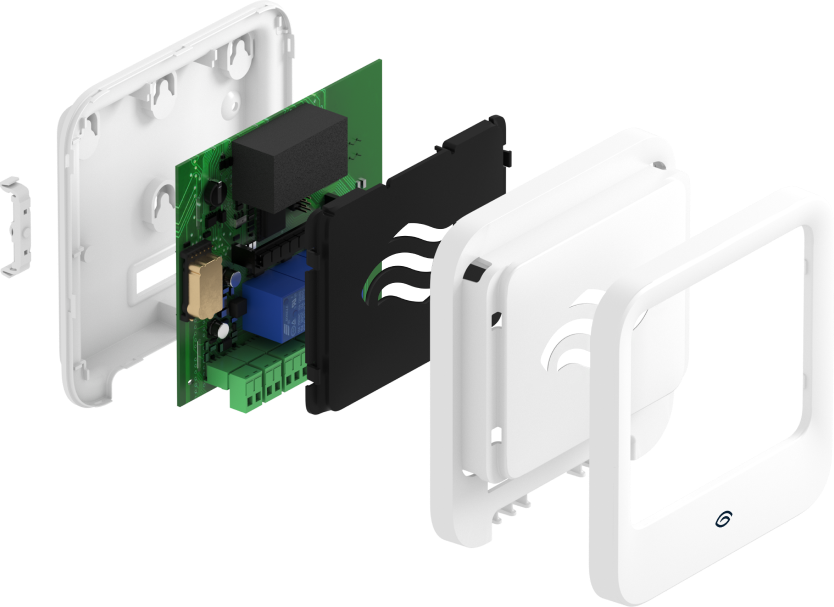

Air and Aqua were intentionally designed as separate controllers. This enables easier and more affordable scaling of systems, as users can add exactly the functionality needed. Nothing more, nothing less.

Whilst you can set parameters manually without the cloud subscription, using it unlocks Aqua’s full potential and maximises the capabilities of your farm.

Control and monitor the conditions on your farm remotely using the Visionary Farms app

Achieve better yields with automatic settings and maintenance based on 7+ years of research

Gain valuable insights into your farm from Aqua’s sensors

From our plant science experts personalised to the varieties you are growing

Automatic task scheduling and delegation among farm team members, notifications of any issues

From our software and hardware engineers and plant science experts

Fine-tune your hydroponic system and manage it remotely using the Visionary Farms app. Save operations and sensor data and export it for analysis.

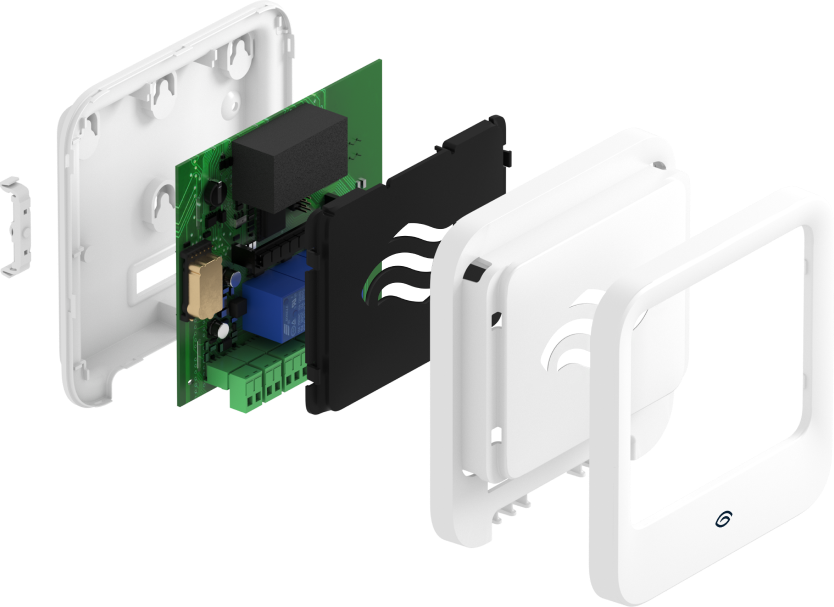

The controller’s fuse protects the circuit from current surges above 0.3A, and is easily replaceable.

Here you can check specific details about Aqua. If you’re unclear, feel free to contact our team using the form below.